The Siser Color Guide is an essential tool for crafters and designers, offering a comprehensive swatch book of standard, specialty, and custom heat transfer vinyl colors and finishes.

What is the Siser Color Guide?

The Siser Color Guide is a comprehensive swatch book showcasing the extensive range of colors and finishes available in Siser heat transfer vinyl. It includes standard colors, specialty finishes like metallic, glitter, and holographic, as well as custom options. Designed to help crafters, designers, and heat transfer enthusiasts, this guide ensures color accuracy and consistency. It features detailed swatches with color names, codes, and finishes, making it easier to select the perfect hue for projects. The guide also highlights the unique properties of each vinyl type, such as durability and texture, ensuring users achieve professional results. Whether for personal crafts or commercial use, the Siser Color Guide is an indispensable resource for anyone working with heat transfer vinyl.

History and Evolution of Siser Heat Transfer Vinyl

Siser Heat Transfer Vinyl has a rich history dating back to its establishment as a leader in the craft and apparel industries. Known for its high-quality materials, Siser has evolved from offering basic heat transfer vinyl to a wide range of innovative products, including specialty finishes like glitter, holographic, and metallic. Over the years, Siser has expanded its product line to meet the growing demands of crafters and professionals, ensuring durability and vibrant colors. The brand has also embraced digital printing technology, introducing materials like Colorprint PU for advanced applications. With a commitment to quality and innovation, Siser remains a trusted name, continuously updating its offerings to align with industry trends and customer needs.

Importance of Color Accuracy in Heat Transfer Vinyl

Color accuracy is crucial in heat transfer vinyl, as it directly impacts the final appearance and professionalism of a design. Inconsistent or mismatched colors can lead to a loss of brand identity and customer satisfaction. Siser’s color guide ensures that crafters and professionals can achieve precise shades, maintaining the integrity of their designs. With a wide range of options, from standard colors to specialty finishes, the guide helps users select the perfect hue for their projects. Accurate color representation is essential for creating visually appealing and durable designs, making the Siser Color Guide an indispensable resource for achieving professional results in heat transfer vinyl applications.

Understanding the Siser Color Palette

The Siser Color Palette offers a wide range of vibrant, durable colors and finishes, from classic solids to metallics and glitters, ensuring precise shade selection for any project.

Standard Colors in the Siser Color Guide

The Siser Color Guide features an extensive range of standard colors, including classic shades like black, white, red, blue, green, and yellow. These colors are designed to be versatile and durable, ensuring long-lasting results for various crafting projects. The standard palette offers a wide variety of options, from neutral tones to vibrant hues, catering to different design preferences. Crafters and designers can rely on these colors for consistency and accuracy, as they are carefully formulated to maintain their vibrancy even after multiple washes and uses. The standard colors are a cornerstone of the Siser product line, providing a solid foundation for any heat transfer vinyl project. Their popularity stems from their reliability and universal appeal.

Specialty Colors and Finishes

The Siser Color Guide also showcases an array of specialty colors and finishes, offering unique visual effects to enhance creative projects. These include glitter, holographic, metallic, neon, fluorescent, and flock options, each designed to add a distinctive touch. Glitter vinyl, for instance, provides a shimmering effect, while holographic finishes create a dynamic, light-reflective appearance. Metallic colors mimic the look of polished metals, and neon shades deliver vibrant, eye-catching results. Fluorescent options glow under UV light, adding an extra dimension to designs. Flock finishes, on the other hand, offer a soft, velvety texture. These specialty colors and finishes expand the possibilities for crafters, allowing them to create intricate, multi-dimensional designs that stand out. They are perfect for adding flair to custom apparel, accessories, and decorative items.

Types of Siser Heat Transfer Vinyl

Siser offers various heat transfer vinyl types, including standard, specialty (glitter, holographic), and tools like weeders, catering to diverse crafting needs and creative applications.

Standard Heat Transfer Vinyl

Standard Heat Transfer Vinyl (HTV) from Siser is a popular choice for crafters and designers, offering a wide range of colors and finishes. It is known for its durability and ease of use, making it ideal for various projects like t-shirts, bags, and fabric decorations; Available in matte, glossy, metallic, and neon finishes, standard HTV provides vibrant colors that retain their quality even after multiple washes. The vinyl is compatible with most cutting machines and can be heat pressed at temperatures between 280°F and 320°F (138°C to 160°C). Siser’s standard HTV is stretchable, ensuring it moves with the fabric without cracking. This versatility and color consistency make it a go-to option for both beginners and professionals in the crafting community.

Specialty Vinyl (Glitter, Holographic, etc.)

Siser’s specialty vinyls, such as glitter and holographic, add unique visual effects to projects. Glitter vinyl offers a sparkly finish available in various colors, while holographic vinyl provides an iridescent sheen. These vinyls are ideal for creating eye-catching designs on apparel, accessories, and fabric. Durable and easy to apply using heat presses, they maintain vibrancy even after multiple washes. Compatible with cutting machines, they suit crafters and professionals seeking to enhance their designs with distinctive finishes. These options expand creative possibilities, allowing for dynamic and visually striking outcomes in various crafting applications.

Color Matching Tools and Resources

The Siser Color Guide offers tools like the Siser App for digital color matching and physical swatch books for accurate color selection and previewing finishes before application.

Using the Siser App for Color Matching

The Siser App is a digital tool designed to simplify color matching and selection. It allows users to preview colors and finishes from the Siser Color Guide digitally, ensuring accuracy. The app provides a detailed view of each shade, helping crafters and designers make informed decisions. Additionally, it offers features like inventory checking and care instructions for specific vinyl types. By utilizing the app, users can streamline their workflow and achieve consistent results. It’s a handy resource for both beginners and experienced crafters, ensuring optimal color accuracy and finish selection for their projects.

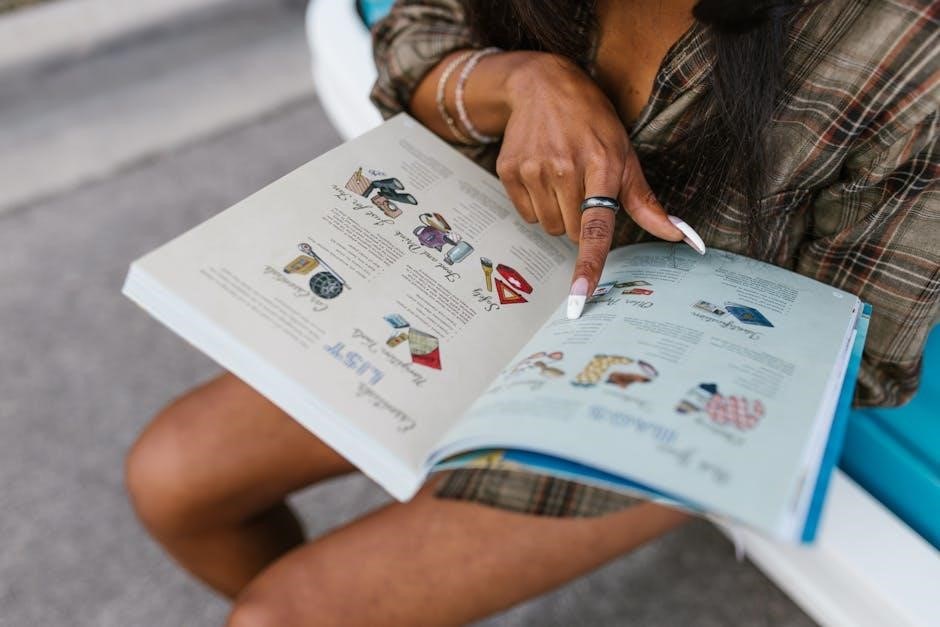

Physical Color Guides and Swatch Books

Physical color guides and swatch books from Siser provide a tangible way to explore and compare the vast range of heat transfer vinyl colors and finishes. These tools feature actual material samples, allowing for accurate color matching and texture assessment. Crafters and designers can easily preview how colors will appear on finished products. The guides include both standard and specialty colors, such as Glitter and Holographic finishes. By having a physical reference, users can make informed decisions quickly and efficiently. Siser’s color guides are widely regarded as indispensable resources for achieving precise color consistency in crafting projects. They are available through authorized distributors or online, ensuring accessibility for all users.

Application and Usage Tips

Applying Siser heat transfer vinyl requires precise techniques to ensure durability and vibrant colors. Always use a Teflon sheet or pillow to prevent damage and promote even heat transfer. Preheat your press to the recommended temperature (typically 300°F for standard vinyl). Cut designs in reverse (mirror image) and weed excess material carefully. Apply firm pressure and moderate time, adhering to Siser’s guidelines for specific vinyl types. For multi-color designs, layer carefully to avoid overlapping. Allow the garment to cool before washing to set the vinyl. Store leftover vinyl in a dry, cool place to maintain quality. Proper application ensures long-lasting, professional-looking results.

Basic Application Techniques

Start by preheating your heat press to the recommended temperature (typically 300°F for standard vinyl). Place a Teflon sheet or pillow inside the press to protect the vinyl and ensure even heat distribution. Cut your design using a cutter or laser, remembering to mirror the image for proper alignment. Weed excess vinyl carefully, leaving only the desired design. Position the vinyl on the garment, ensuring it is centered and smooth. Apply firm pressure and moderate heat for the recommended time (usually 10-15 seconds). Allow the garment to cool slightly before peeling the carrier sheet. For best results, avoid washing the garment for at least 24 hours. This basic method ensures a professional finish and long-lasting durability.

Advanced Tips for Multi-Color Designs

For multi-color designs, precision and planning are key. Use layering techniques, ensuring each color is pressed separately to avoid overlapping. Align each layer carefully, utilizing a laser cutter for intricate cuts. Pre-press the garment for 2-3 seconds to remove moisture and ensure better adhesion. Apply firm pressure and adjust temperature based on vinyl type (e.g., lower for specialty finishes like glitter). Allow each layer to cool slightly before adding the next to prevent damage. Use a Teflon pillow for even heat distribution and a heat-resistant tape to secure alignment. Test designs on scrap fabric first and consult the Siser App for color compatibility. This method ensures vibrant, professional results for complex designs.

Care and Maintenance

Wash garments inside out in cold water, avoiding bleach or harsh detergents. Store vinyl in a cool, dry place, away from direct sunlight to maintain color vibrancy and prevent damage.

Washing Instructions for Siser Vinyl

Proper care ensures longevity of Siser vinyl designs. Wash garments inside out in cold water using mild detergent. Avoid bleach or fabric softeners, as they may degrade vinyl. Tumble dry on low or air-dry to prevent cracking. Ironing should be done on the reverse side using low heat without steam. This preserves the vinyl’s adhesive and color integrity. For best results, wash garments before first wear and avoid repeated washing. Turn inside out before washing to protect the design. These steps ensure vibrant colors and durability of Siser heat transfer vinyl. Follow these guidelines to maintain the quality and appearance of your designs.

Storage and Handling Tips

Store Siser vinyl rolls in a cool, dry place away from direct sunlight to prevent color fading. Keep them upright or horizontally to avoid creasing. Handle vinyl with clean, dry hands to prevent oils from affecting adhesion. Use a Teflon sheet or parchment paper when cutting to avoid damage. Store leftover vinyl in its original packaging or airtight containers to maintain quality. Avoid bending or folding rolls excessively, as this can cause cracks. Always ensure the cutting mat and tools are clean to prevent contamination. Proper storage and handling extend the vinyl’s shelf life and ensure optimal performance during application. Regularly inspect rolls for dust or debris before use for best results.

Troubleshooting Common Issues

Address color fading and peeling by ensuring proper application and wash care. Use a Teflon sheet during cutting to prevent damage. Refer to Siser’s care guide for solutions.

Color Fading and Durability Issues

Color fading and durability issues with Siser heat transfer vinyl can occur due to improper application, washing, or exposure to harsh conditions. To prevent fading, ensure proper weeding, application temperature (between 280°F-300°F), and pressure. Avoid using fabric softeners or bleach, as they can degrade the vinyl. For optimal durability, wash garments inside out in cold water and dry on a low setting. Using a Teflon pillow during pressing can help prevent damage. If fading occurs, reapplying or replacing the vinyl may be necessary. Refer to Siser’s care guide for detailed instructions to maintain vibrant colors and extend the life of your designs. Proper storage and handling also play a crucial role in preserving vinyl quality.

Peeling and Adhesion Problems

Peeling and adhesion issues with Siser heat transfer vinyl often arise from improper application or surface preparation. Ensure the fabric is clean, dry, and free of residue before pressing. Use the recommended temperature (280°F-300°F) and pressure to ensure proper adhesion. If peeling occurs, check for insufficient heat or pressure during application. Repressing the design with proper settings can sometimes resolve the issue. Avoid using fabric softeners or oils, as they can weaken the vinyl’s bond. For particularly delicate fabrics, a Teflon pillow can help distribute heat evenly. Store unused vinyl in a cool, dry place to maintain its adhesive properties. If the problem persists, consult the Siser care guide or contact their support for further assistance.

The Siser Color Guide is a must-have resource for crafters, offering versatility and inspiration. It ensures color accuracy and durability, while future trends promise even more creative possibilities.

Why the Siser Color Guide is Essential for Crafters

The Siser Color Guide is a must-have resource for crafters, offering a vast palette of standard and specialty colors. It ensures color accuracy and consistency, which are critical for professional and personal projects. With its detailed swatches, crafters can easily match colors and finishes, streamlining the design process. The guide also introduces new trends, inspiring creativity and innovation. Whether for heat transfer vinyl, glitter, or holographic finishes, it provides unparalleled convenience. Its portability and comprehensive coverage make it indispensable for achieving precise results. This tool not only enhances craftsmanship but also ensures durability and vibrancy in every design, making it a cornerstone for any crafter’s toolkit.

Future Trends in Heat Transfer Vinyl Colors

Future trends in heat transfer vinyl colors are expected to focus on innovation and sustainability. Siser is expanding its range with new finishes like neon, metallic, and textured options. The introduction of eco-friendly materials and recyclable vinyl is anticipated, aligning with global sustainability goals. Customization will continue to dominate, with tools like the Siser App enabling precise color matching. Vibrant, bold hues and unique effects, such as holographic and iridescent finishes, will gain popularity. Additionally, advancements in technology will allow for faster production of specialty colors, catering to the growing demand for personalized designs. These trends will ensure that heat transfer vinyl remains a dynamic and versatile medium for crafters and designers alike, offering endless creative possibilities.