Efficiency of dc motor pdf

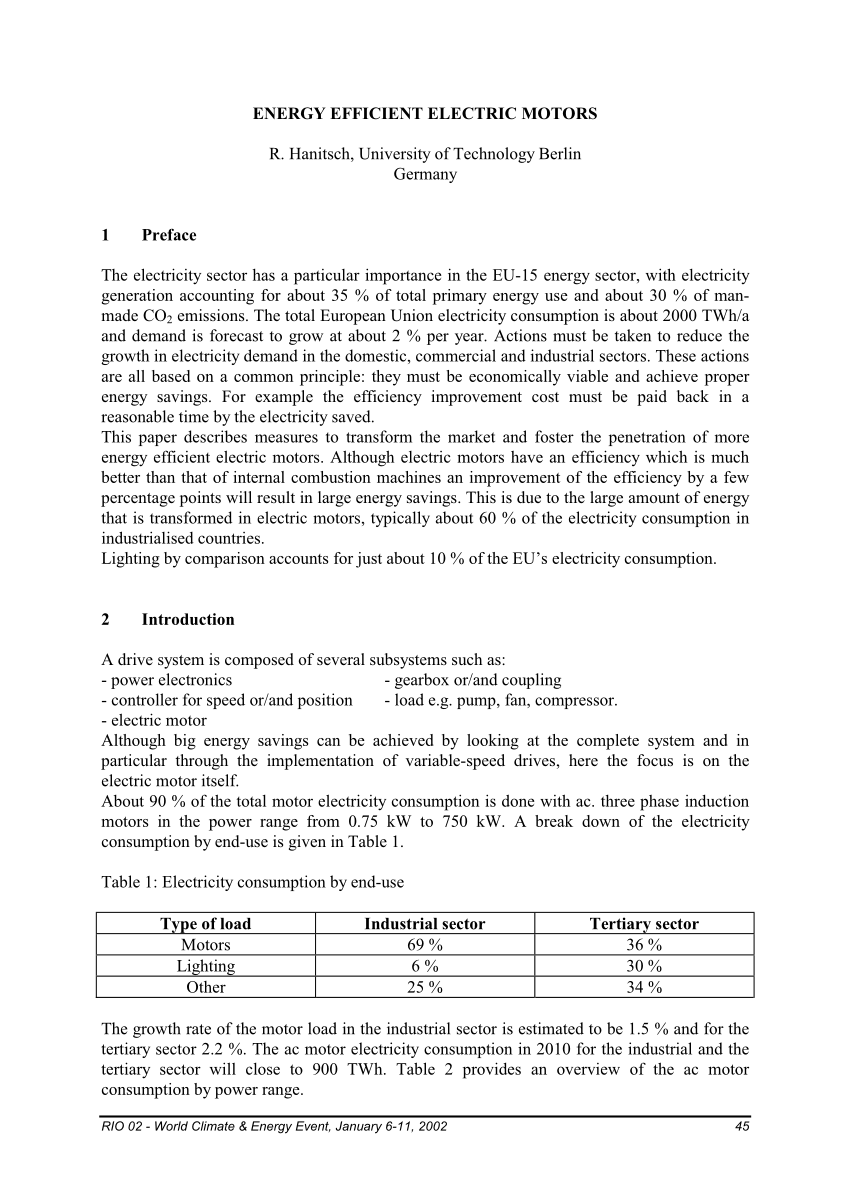

The efficiency of a dc machine depends upon the losses.3/7/2011 Comparison of three types of Motor 1) The speed regulation in shunt motor is better than series motor 2) The starting torque of a series motor is more than other motor 3) Both shunt and compound motors have definite no load speed. The smaller the losses. the greater is the efficiency of the machine. 17 . There are several tests to

motor is not totally different from the conventional DC motor. The major thing addition is the phase involved which affects the overall result of the BLDC model.

A dc generator converts mechanical power into electrical power and a dc motor converts electrical power into mechanical power. Thus, for a dc generator, input power is in the form of mechanical and the output power is in the form of electrical.

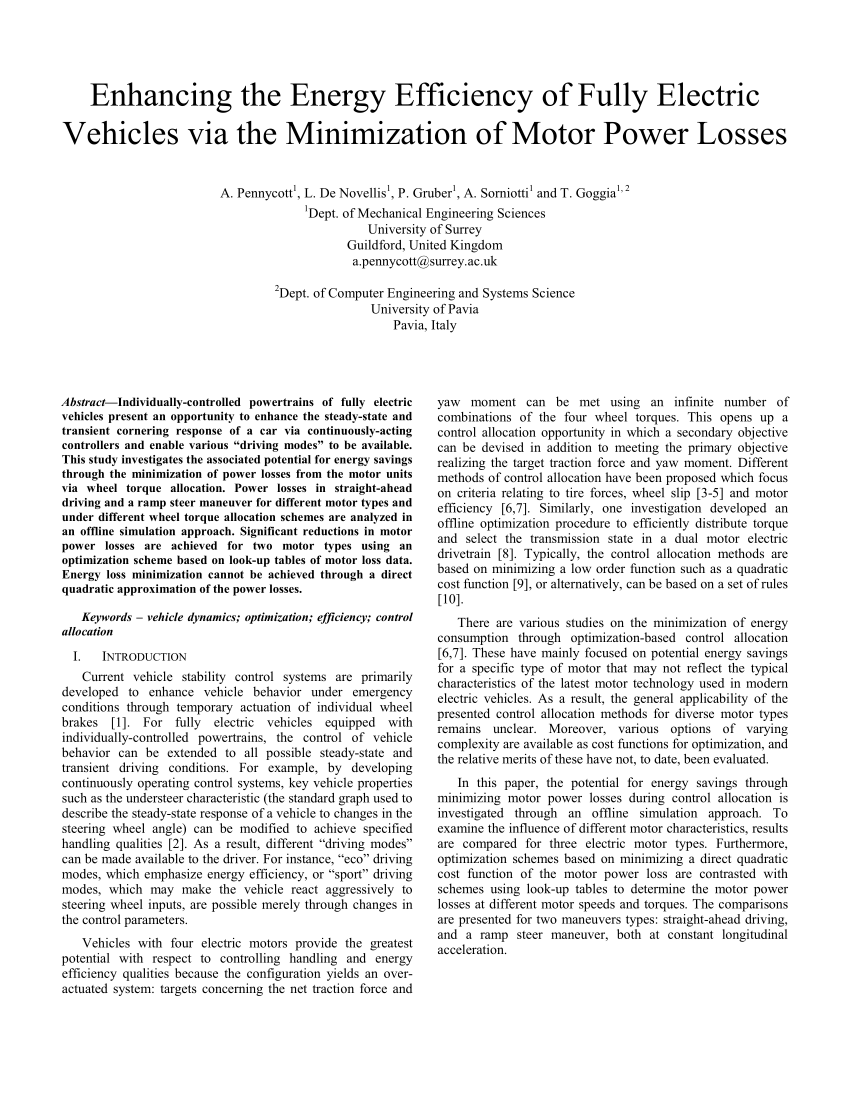

Efficiency Comparison of Trapezoidal and Sinusoidal Method for Brushless DC Motor Drive Article (PDF Available) in Applied Mechanics and Materials 785(2015):248-252 · April 2015 with 3,524 Reads

Improved Efficiency Electronic Speed Controller Development for 3-Phase Brushless DC Motor in Unmanned Aerial Systems Kun Li , Ao Chen, Kun Zhang and Ben M. Chen Department of Electrical and Computer Engineering, NUS, Singapore, 117576 ABSTRACT This paper presents the methodology and tech-nique of implementing vector control method on brushless DC (BLDC) motors. Traditional scalar …

Hardware Design Considerations for an Efficient Vacuum Cleaner Using a BLDC Motor Application Report SLVA654A–June 2014–Revised July 2015 Hardware Design Considerations for an Efficient Vacuum Cleaner Using a BLDC Motor NickOborny ABSTRACT A vacuum cleaner is a device that uses an air pump to create a partial vacuum to suck up dirt and dust particles from a given surface. …

The efficiency of a motor is equal to the mechanical output power that it can deliver, divided by the power which it absorbs. The output power and the absorbed power vary in relation to the speed

Motor is an appliance to covert electrical energy into mechanical energy in order to move or to operate a machine e.g. compressor, fan or pump. The efficiency of energy convertion is an

MOTION CONTROL PWM Control Methods Increases Efficiency, Reliability and Extend Battery Lifetime Brushless DC motors the choice for battery-operated applications

Electric Motor Efficiency under Variable Frequencies and Loads http://www.itrc.org/reports/pdf/r06004.pdf ITRC Report No. R 06-004 Electric Motor Efficiency

To make best use of the limited supply of electrical energy, the bike is equipped with a high-efficiency Lynch axial-gap dc motor. This type of low-voltage, high-torque, permanent-magnet dc motor has the added advantage of a high power density. Lynch motors are today manufactured in the UK by the Lynch Motor Company in three frame sizes and with numerous options. Alternatively two motors can

This paper presents an efficiency comparison and verification of two types of Brushless DC (BLDC) motors and drives combination. The trapezoidal BLDC motor is excited by trapezoidal drive and

Electrical motor efficiency is the ratio between shaft output power – and electrical input power. Electrical Motor Efficiency when Shaft Output is measured in Watt

(PDF) Efficiency Comparison of Trapezoidal and Sinusoidal

EFFICIENCY COMPARISON OF MODERN Brushless Motors

Improving BLDC Motor Control for Better Efficiency and Performance in Industrial, White and Brown Goods Page 1 Fujitsu Microelectronics America, Inc.

efficiency of the motor at any loading condition. Let the motor be loaded such that new current Let the motor be loaded such that new current drawn from the supply is L and the new armature current is I I a as shown in figure 40.4.

Designing High-Performance and Power Efficient 3-Phase Brushless DC Motor Control Systems April 17, 2014 Revision 2.1 The use of BLDC motors in …

To make the best use of the limited supply of electrical energy, the bike is equipped with a high-efficiency Lynch axial-gap dc motor. This type of low-voltage, high-torque, permanent-magnet dc motor has the added advantage of a high power density. Lynch motors are today manufactured in the UK by the Lynch Motor Company in three frame sizes and with numerous options. Alternatively two motors

and also account for any efficiency losses in the system (Control, Motor, Gearbox, and Coupling Efficiencies). Additionally, the voltage type (AC or DC) must match the motor type or be

BLDC motors are typically 85–90% efficient or more. Efficiency for a BLDC motor of up to 96.5% have been reported,[64] whereas DC motors with brushgear are typically 75–80% efficient

motor efficiency distribution. – Apparent Efficiency. This is the product of a motor’s efficiency and power factor. Figure 2.1 – Typical energy flow of standard motors [2]. B. Motor Losses Energy losses are the determining factor in motor efficiency. These losses can be divided in five classes: Name Percent of Total Losses Description Fixed or Variable How to reduce Core Losses 15-15%

improve the motor efficiency, the flux must be reduced, sidered to be an ideal system, where the DC voltage at the input of the inverter has no AC component, and the output voltage of the filter at the output of the inverter has no harmonics. For sinusoidal pulse width modula-tion SPWM, the ratio of the amplitude of the sinusoidal waveform to the amplitude of the triangular waveform is

Friction is reduced and brush dc motor efficiency is improved by low-resistance commutators and collectors in brush DC motors. Our advanced design allows us to build motors with closer tolerances, narrowing the air gap between the rotor and the stator and resulting in …

Brake motors, if the brake is an integral component of the inner motor-construction and can be neither removed nor separately operated during the testing of motor-efficiency. Submersible motor, which are specifically designed to be operated completely immersed in liquid.

by the YFD, and losses in the motor due to the motor duty-point movement (i.e., the change in input power requirement for the pump at the location of the intersection between the pump curve

Determination of Efficiency The efficiency of DC machine like any other machine is determined by the ratio of output power to that of the input power.

The motor we wish to determine the efficiency of is used to lift the mass m a distance h. The photogate The photogate provides the computer with the number of …

Abstract – This paper deals with the calculation of the efficiency for a Brushless DC Motor when used for traction applications in order to determine the optimum operating conditions which will …

EFFICIENCY COMPARISON OF MODERN VARIABLE SPEED DRIVE TECHNOLOGIES JUNE 1993 BY EDWARD C. LEE POWERTEC INDUSTRIAL CORPORATION . Abstract: Brushless D.C. technology is new to the general industrial maketplace and is one of the new technology variable speed drives. Efficiency and performance comparisons will be made between the various technologies …

Technical report on energ y efficiency in small DC motors . The maxon academy have released a new two part technical report into the energy efficiency of small DC motors…

• High efficiency • Long operating life • Noiseless operation • Higher speed ranges In addition, the ratio of torque delivered to the size of the motor is higher, making it useful in applications where space and weight are critical factors. In this application note, we will discuss in detail the con-struction, working principle, characteristics and typical applications of BLDC motors

Brushless Motor Efficiency and Constants Before looking at Brushless motor efficiency, we must first quickly cover the Motor Constants applicable for determining the efficiency of a brushless motor. There are three important motor constants that allow you to understand the performance of any electric brushless motor.

Therefore, the efficiency of a DC generator will always be maximum once the load current is such that variable loss is the same to the constant loss. The fig shows the deviation of efficiency …

C12-4 DEVELOPMENT OF HIGH EFFICIENCY BRUSHLESS DC MOTOR WITH NEW MANUFACTURING METHOD OF STATOR FOR COMPRESSORS Tomoaki Oikawa …

EFFICIENCY COMPARISON Motor effi ciency is one factor that can signifi cantly affect running costs of any motor under given set of conditions. Small improvements in effi ciencies can result in big savings in annual running costs. Consider following comparison of running costs between previous MEPS# compliant Standard Effi ciency motors versus High Effi ciency motors complying with MEPS

This 15W, 12-mm x 20-mm, power stage reference design drives and controls the position of the brushed DC (BDC) motor operating from a three to six cell Li-ion battery. This highly efficient solution is optimized with a very small form factor that easily fits into the motor, and supports precise moto

”Neo”Magnets Raise the Efficiency of Electric Motors Higher-efficiency motors reduce the load on the alternator and improve a car’s fuel economy.

FEA of a High Efficiency Brushless DC Motor Design Manoj Kumar Pandey, Dr. Anurag Tripathi and Dr. Bharti Dwivedi 1Research Scholar, Faculty of Electrical Engineering, Dr. APJ Abdul Kalam Technical University Lucknow, India.

Efficiency expresses the energy losses inherent in the construction of the motor, and the ratio of power delivered at the shaft to power input. Power factor is a form of electrical efficiency due to voltage and current waveforms being out

Dc motors deliver high performance and efficiency for

Advantages of a Toshiba High Efficiency induction motor: Peak efficiencies provide maximum energy savings for each output Extensive range of customisation options

Efficiency of DC Generator Efficiency is simply defined as the ratio of output power to the input power. Let R = total resistance of the armature circuit (including the brush contact resistance, at series winding resistance, inter-pole winding resistance and compensating winding resistance).

I’m doing a lab report for a shunt DC motor evaluation. I seem to be stuck on the efficiency vs torque of the motor. I have plotted a graph of measured $frac{P_{out}}{P_{in}}cdot 100%$, which shows that the motor becomes less effcient with more load.

The category of DC motor that is the least expensive, easiest to use, and thus the most popular, is the sub- fractional horsepower permanent magnet brushed DC motor. “ …

Brushed DC Motor Fundamentals. AN905 DS00905B-page 2 2010 Microchip Technology Inc. Brushes and Commutator Unlike other electric motor types (i.e., brushless DC, AC induction), BDC motors do not require a controller to switch current in the motor windings. Instead, the commutation of the windings of a BDC motor is done mechanically. A segmented copper sleeve, called a commutator, resides on

DC Motors 3 4.3. DC Motor Basic Principles 4.3.1 Energy Conversion If electrical energy is supplied to a conductor lying perpendicular to a magnetic field, the interaction of current flowing in the conductor and the magnetic field will produce mechanical force (and therefore, mechanical energy). 4.3.2 Value of Mechanical Force There are two conditions which are necessary to produce a force on – gaz effet de serre pdf

Technical report on energy efficiency in small DC motors

Electric Motor Efficiency under Variable Frequencies and Loads

DC motor efficiency which formula to use? Electrical

Dc motors deliver higher performance and efficiency

Improving Brushless DC Motor Control for Better Efficiency

Electric Motor Efficiency Brush DC Motors Portescap

TIDA-01588 10.8-V/15-W >90% Efficiency 2.4-cm2 Power

https://en.wikipedia.org/wiki/Fractional-horsepower_motor

Lesson 17 DC Motors Part II USNA

detail english 5 2016 cost effective building pdf – High Efficiency Series Motors Toshiba International

Twenty Ways to Optimize Energy Efficiency in the Use of

Is a brushless DC motor more energy efficient than a

Efficiency of DC Generator- Maximum Efficiency Circuit Globe

Electric Motor Efficiency Brush DC Motors Portescap

Hardware Design Considerations for an Efficient Vacuum Cleaner Using a BLDC Motor Application Report SLVA654A–June 2014–Revised July 2015 Hardware Design Considerations for an Efficient Vacuum Cleaner Using a BLDC Motor NickOborny ABSTRACT A vacuum cleaner is a device that uses an air pump to create a partial vacuum to suck up dirt and dust particles from a given surface. …

motor efficiency distribution. – Apparent Efficiency. This is the product of a motor’s efficiency and power factor. Figure 2.1 – Typical energy flow of standard motors [2]. B. Motor Losses Energy losses are the determining factor in motor efficiency. These losses can be divided in five classes: Name Percent of Total Losses Description Fixed or Variable How to reduce Core Losses 15-15%

”Neo”Magnets Raise the Efficiency of Electric Motors Higher-efficiency motors reduce the load on the alternator and improve a car’s fuel economy.

by the YFD, and losses in the motor due to the motor duty-point movement (i.e., the change in input power requirement for the pump at the location of the intersection between the pump curve

Efficiency expresses the energy losses inherent in the construction of the motor, and the ratio of power delivered at the shaft to power input. Power factor is a form of electrical efficiency due to voltage and current waveforms being out

DC Motors 3 4.3. DC Motor Basic Principles 4.3.1 Energy Conversion If electrical energy is supplied to a conductor lying perpendicular to a magnetic field, the interaction of current flowing in the conductor and the magnetic field will produce mechanical force (and therefore, mechanical energy). 4.3.2 Value of Mechanical Force There are two conditions which are necessary to produce a force on

To make the best use of the limited supply of electrical energy, the bike is equipped with a high-efficiency Lynch axial-gap dc motor. This type of low-voltage, high-torque, permanent-magnet dc motor has the added advantage of a high power density. Lynch motors are today manufactured in the UK by the Lynch Motor Company in three frame sizes and with numerous options. Alternatively two motors

Advantages of a Toshiba High Efficiency induction motor: Peak efficiencies provide maximum energy savings for each output Extensive range of customisation options

Abstract – This paper deals with the calculation of the efficiency for a Brushless DC Motor when used for traction applications in order to determine the optimum operating conditions which will …

Electrical motor efficiency is the ratio between shaft output power – and electrical input power. Electrical Motor Efficiency when Shaft Output is measured in Watt

• High efficiency • Long operating life • Noiseless operation • Higher speed ranges In addition, the ratio of torque delivered to the size of the motor is higher, making it useful in applications where space and weight are critical factors. In this application note, we will discuss in detail the con-struction, working principle, characteristics and typical applications of BLDC motors

I’m doing a lab report for a shunt DC motor evaluation. I seem to be stuck on the efficiency vs torque of the motor. I have plotted a graph of measured $frac{P_{out}}{P_{in}}cdot 100%$, which shows that the motor becomes less effcient with more load.

Efficiency Comparison of Trapezoidal and Sinusoidal Method for Brushless DC Motor Drive Article (PDF Available) in Applied Mechanics and Materials 785(2015):248-252 · April 2015 with 3,524 Reads

Is a brushless DC motor more energy efficient than a

Twenty Ways to Optimize Energy Efficiency in the Use of

Electric Motor Efficiency Brush DC Motors Portescap

A dc generator converts mechanical power into electrical power and a dc motor converts electrical power into mechanical power. Thus, for a dc generator, input power is in the form of mechanical and the output power is in the form of electrical.

DC motor efficiency which formula to use? Electrical

Lesson 17 DC Motors Part II USNA

Designing High-Performance and Power Efficient 3-Phase

• High efficiency • Long operating life • Noiseless operation • Higher speed ranges In addition, the ratio of torque delivered to the size of the motor is higher, making it useful in applications where space and weight are critical factors. In this application note, we will discuss in detail the con-struction, working principle, characteristics and typical applications of BLDC motors

L-40 TB ET EE NPTEL

DC MotorsRU Electric Motor Electric Current